Basic Details

| San Precision Alloys | |

| siachen.com/sanprecisionalloys | |

| Private Limited | |

| 2011 | |

| IN | |

| TN | |

| coimbatore |

Communication

| SF.NO 225/226 PT, Kondampatti to Arasampalayam Road, Kinathukkadavu (TK), Coimbatore - 641 202, Tamil Nadu, India. | |

| +9188700 04850 | |

About Business

Business Summary

San Precision Alloys, leading investment casting manufacturer and exporter in India.

Business Description

Discover precision in casting with San Precision, leading casting manufacturers in Coimbatore. Our commitment to excellence ensures top-quality castings that meet industry standards. Partner with us for reliability, accuracy, and innovation in every casting solution. Our Casting is mainly utilized in the production of components for power generation equipment, including turbines and generator parts. In the oil and gas industry, a variety of critical components, including valves, pumps, and pipeline fittings, often necessitate precision casting. This method ensures the production of high-quality and durable parts that meet the demanding requirements of the industry.

Our casting manufacturing process leverages cutting-edge technology and rigorous quality control measures to ensure each product adheres to the highest standards. Whether it's intricate components or large-scale industrial parts, our precision casting capabilities are tailored to meet the unique needs of our clients.

The global reach of San Precision is underscored by our robust export division, which facilitates the seamless delivery of our products to clients worldwide. Committed to customer satisfaction, we prioritize timely deliveries and ensure that our castings reach their destination with the utmost care.

As a company deeply rooted in ethical business practices, San Precision adheres to environmental and sustainability standards throughout its manufacturing processes. Our dedication to quality, precision, and responsible manufacturing has earned us the trust of clients across the globe, making San Precision a preferred choice in the casting industry. Experience the pinnacle of casting excellence with San Precision Alloys - where precision meets perfection, and innovation knows no bounds.

To get more auto components call us : +91 88700 04850, +91 98940 14851.

Detailed Business Description

San Precision Alloys - Precision Casting Manufacturers in Coimbatore

Welcome to San Precision Alloys, the leading casting manufacturers in Coimbatore. We specialize in providing top-quality castings that meet industry standards with a commitment to excellence. Our precision casting solutions are known for reliability, accuracy, and innovation, making us a trusted partner for various industries. With a focus on quality and customer satisfaction, we ensure that every product we deliver exceeds expectations.

1. Introduction

San Precision Alloys is a renowned name in the precision casting industry, known for its superior quality products and innovative solutions. Our mission is to provide exceptional casting services that meet the diverse needs of our clients while upholding the highest standards of quality and reliability. We take pride in our commitment to excellence and strive to be the preferred choice for precision casting solutions in Coimbatore and beyond.

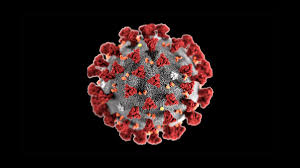

2. About Business Sector

The precision casting sector plays a crucial role in various industries, including power generation and oil & gas. Precision casting involves the production of complex components with high accuracy and intricate details, making it essential for the manufacturing of critical parts such as turbines, valves, pumps, and pipeline fittings. The sector serves a wide range of industries that require precision-engineered components to ensure optimal performance and durability.

The latest trends in the precision casting sector focus on advanced technologies and materials that enhance the quality and efficiency of the casting process. With a growing emphasis on sustainability and environmental responsibility, companies like San Precision Alloys are adopting eco-friendly practices to minimize their impact on the environment. The future prospects of the sector look promising, with increased demand for high-quality precision castings in various industries worldwide.

3. Primary List of Products and Services

At San Precision Alloys, we offer a wide range of precision casting products and services tailored to meet the unique needs of our clients. Our primary products include:

- Complex components for power generation equipment

- Critical parts for the oil and gas industry

- Industrial components for various applications

In addition to our casting products, we also provide services such as precision machining, finishing, and quality testing to ensure that every product meets the highest standards of quality and performance.

4. Company History & Founding

San Precision Alloys was founded with a vision to revolutionize the precision casting industry by delivering top-quality products and exceptional customer service. Our journey from a small manufacturing unit to a leading casting manufacturer in Coimbatore is marked by significant milestones and continuous growth. Over the years, we have built a reputation for excellence and reliability, becoming a trusted name in the industry.

5. Unique Value Proposition

What sets San Precision Alloys apart from its competitors is our unwavering commitment to quality, innovation, and customer satisfaction. We strive to deliver value to our customers by providing precision castings that meet the highest standards of accuracy and performance. Our focus on continuous improvement and technological advancements ensures that we stay ahead of the curve and offer cutting-edge solutions to our clients.

6. Trustworthiness

At San Precision Alloys, trustworthiness is at the core of our business values. We have earned a reputation as a reliable partner and solution provider through our commitment to transparency, ethics, and integrity in all our dealings. Our customers trust us to deliver on our promises and provide them with high-quality products that meet their exact specifications. With a focus on building long-term relationships, we prioritize customer trust and satisfaction above all else.

7. Management Team

Our management team at San Precision Alloys comprises seasoned professionals with extensive experience in the precision casting industry. Led by visionary leaders, our team brings together a diverse set of skills and expertise to drive the company's success and growth. With a focus on innovation and continuous improvement, our management team plays a pivotal role in shaping the company's strategic direction and ensuring its long-term sustainability.

8. Unique Services

One of the unique services that San Precision Alloys offers is our customized precision casting solutions tailored to meet the specific requirements of our clients. We work closely with our customers to understand their needs and provide them with innovative casting solutions that enhance the performance and durability of their products. Our focus on quality and precision sets us apart from other casting manufacturers, making us a preferred choice for companies seeking reliable and high-quality casting solutions.

9. Foundations of Our Business Success

Our success at San Precision Alloys is built on a foundation of exceptional customer service and a relentless commitment to exceeding customer expectations. We go above and beyond to ensure that our customers receive the highest quality products and services, backed by our dedication to quality, reliability, and innovation. By prioritizing customer satisfaction and building strong relationships, we have established ourselves as a trusted partner in the precision casting industry.

10. Our Innovation Strategy and Future Plans

At San Precision Alloys, innovation is at the heart of everything we do. We are constantly exploring new technologies and processes to improve our casting capabilities and offer cutting-edge solutions to our clients. Our future plans involve expanding our product range, enhancing our manufacturing processes, and diversifying into new industry sectors. With a clear vision for the future and a focus on continuous improvement, we are poised to lead the way in the precision casting industry and deliver exceptional products and services to our customers.

11. Conclusion

In conclusion, San Precision Alloys is your trusted partner for precision casting solutions that meet the highest standards of quality and performance. With a focus on excellence, innovation, and customer satisfaction, we strive to deliver value to our clients and exceed their expectations. Choose San Precision Alloys for precision casting that meets industry standards and goes above and beyond to deliver superior products and services.

Products / Services

Products and Services Offered by San Precision Alloys

Location 1: SF.NO 225/226 PT, Kondampatti to Arasampalayam Road, Kinathukkadavu (TK), Coimbatore - 641202, Tamil Nadu, India

San Precision Alloys at this location offers a wide range of products and services including:

- Alloy Steel Castings

- Stainless Steel Castings

- Heat Resistant Castings

- Corrosion Resistant Castings

- Machining Services

- Surface Coating Services

Location 2: 53, SIDCO Private Industrial Estate, Kurichi, Coimbatore, Tamil Nadu 641021

At their second location, San Precision Alloys provides the following products and services:

- Aluminium Castings

- Brass Castings

- Custom Metal Castings

- Prototype Development

- Quality Testing and Inspection

- Technical Consultation

Platform Enhanced Sections and Articles

Article by Siachen Editors to aid the customer in decision making

Evaluation Criteria for Vendors in the Metal Casting Industry

Quality of Materials

One of the most important factors to consider when evaluating a vendor for metal casting products is the quality of materials they use. Ensure that the vendor uses high-grade materials such as stainless steel, nickel alloys, or cobalt base casting to guarantee the durability and performance of the final product.

Experience and Expertise

Look for vendors with a proven track record in the industry and years of experience in metal casting. A vendor with expertise in handling different types of metals and complex casting processes is more likely to deliver superior quality products.

Customization Capabilities

Consider whether the vendor offers customization options to meet your specific requirements. The ability to tailor the design, size, and specifications of the metal casting products can ensure they align perfectly with your needs.

Cost and Pricing

Compare the pricing structures of different vendors to find the most cost-effective option without compromising on quality. Request quotes and detailed breakdowns of costs to evaluate the overall value offered by each vendor.

Lead Times and Delivery Schedule

Assess the lead times and delivery schedules provided by vendors to ensure timely production and delivery of metal casting products. Delays in production or shipping can impact your project timelines and budget.

Quality Control and Testing Procedures

Inquire about the vendor's quality control measures and testing procedures to guarantee the reliability and performance of the metal casting products. Look for vendors with certifications and accreditations that demonstrate their commitment to quality.

Customer Reviews and References

Check customer reviews and ask for references from past clients to gauge the vendor's reputation and customer satisfaction levels. Positive feedback and recommendations indicate a reliable and trustworthy vendor.

Conclusion

By considering these key factors when evaluating vendors in the metal casting industry, you can make an informed decision on the best vendor to partner with for your metal casting needs. Prioritize quality, experience, customization options, pricing, lead times, quality control, and customer feedback to ensure a successful collaboration.

Article on latest trends and developments in this type of business

Latest Trends and Developments in the Precision Casting Industry

Introduction

Precision casting, also known as investment casting, is a manufacturing process used to create intricate and complex parts with high accuracy and detail. The industry is constantly evolving, driven by advancements in technology, materials, and customer demands. In this article, we will explore the latest trends and developments shaping the precision casting industry.

Automation and Industry 4.0

One of the key trends in the precision casting industry is the adoption of automation and Industry 4.0 technologies. Automation has revolutionized the casting process, leading to increased efficiency, reduced labor costs, and improved quality control. Robotics and artificial intelligence are being used to streamline production processes, from mold-making to finishing operations.

Subtopic: Robotics and AI in Precision Casting

Robotic systems are being employed to handle tasks that are repetitive or hazardous for human workers. AI algorithms are used to optimize casting parameters, predict defects, and improve overall production efficiency. The integration of these technologies has led to shorter lead times, higher precision, and greater consistency in casting quality.

Advanced Materials and Processes

Another important trend in the precision casting industry is the development of advanced materials and processes. New alloys and composites are being introduced to meet the growing demand for lightweight, high-strength components in industries such as aerospace, automotive, and energy. Additive manufacturing techniques, such as 3D printing, are also being used to create complex geometries with minimal material waste.

Subtopic: Additive Manufacturing in Precision Casting

Additive manufacturing technologies are revolutionizing the way precision castings are produced. 3D printing allows for the creation of intricate designs that would be impossible to achieve using traditional casting methods. This technology offers greater design flexibility, reduced lead times, and lower costs for prototyping and small batch production.

Sustainability and Responsible Manufacturing

In response to growing environmental concerns, the precision casting industry is focusing on sustainability and responsible manufacturing practices. Companies are investing in energy-efficient technologies, recycling programs, and waste reduction initiatives to minimize their environmental impact. Sustainable sourcing of raw materials and adherence to ethical labor practices are also becoming key priorities for industry players.

Subtopic: Green Initiatives in Precision Casting

Many precision casting companies are implementing green initiatives to reduce their carbon footprint and promote sustainability. This includes the use of renewable energy sources, such as solar or wind power, in manufacturing facilities, as well as the development of eco-friendly casting materials. Waste management programs aim to recycle scrap metal and minimize waste sent to landfills.

Globalization and Market Expansion

The precision casting industry is experiencing rapid globalization, with companies expanding their market reach and establishing international partnerships. The rise of e-commerce platforms and digital marketing strategies has made it easier for manufacturers to connect with customers worldwide. Global supply chains and logistics networks are being optimized to ensure timely delivery of products to global markets.

Subtopic: Digital Transformation in Precision Casting

Digital transformation is reshaping the way precision casting companies operate, from product design to customer service. Online platforms are being used to showcase product catalogs, provide instant quotes, and facilitate order processing. Advanced data analytics and cloud-based systems are improving efficiency and transparency in supply chain management.

Conclusion

The precision casting industry is undergoing significant transformation, driven by technological advancements, sustainability initiatives, and global market dynamics. Companies that embrace automation, adopt innovative materials and processes, and prioritize sustainability will be well-positioned to thrive in this competitive landscape. As the industry continues to evolve, staying ahead of the latest trends and developments will be crucial for success in the precision casting market.

Contact Us for Precision Casting Solutions

For top-quality precision casting solutions that meet industry standards, partner with San Precision. With a commitment to excellence, innovation, and sustainability, San Precision is a preferred choice in the casting industry. Experience the pinnacle of casting excellence with San Precision Alloys - where precision meets perfection, and innovation knows no bounds. To learn more about our precision casting capabilities, contact us at +91 88700 04850 or +91 98940 14851. Experience the difference with San Precision today.

Last five profiles from the category:

-

Camlock Fittings – Leading supplier of high-quality camlock fittings, stainless steel ball valves, and brew hardware for various industries – Queensland, Australia.

siachen.com/camlockfittings

Unit 1 10 Boron Street Sumner Park, QLD 4074 Australia land_line : 1300 988 963 -

WeCustomBoxes – Custom Packaging Solutions to Enhance Your Brand with High-Quality, Affordable, and Eco-Friendly Options – Katy, Texas, USA.

siachen.com/wecustomboxes

1997 Katy Mills Blvd, Katy TX 77494, United States. land_line : 12817864001 -

Doocan – India’s best furniture manufacturer leveraging a tech-powered platform for global B2B marketplace solutions – Wilmington, Delaware, United States.

siachen.com/doocan

300 Delaware Ave. Suite 210 #265, Wilmington , DE - 19801, United States. land_line : +919634375566 -

Sydney Steel Fabricators – Premier provider of comprehensive metal services including steel fabrication, welding, and metal supply since 2010 – New South Wales, Australia.

siachen.com/sydneysteelfabricators

Shop 7/363 Sussex St, Sydney NSW 2000, Australia. -

Adco DispleTech – Leading providers of high-quality retail display fixtures and store supplies with over 60 years of innovation – Montreal, Quebec, Canada.

siachen.com/displetechcorp

1310 Rue Chabanel O, Montreal, QC, Canada. land_line : +5143812396