Basic Details

| Krishna Engineering | |

| siachen.com/krishnaengineering | |

| Cooperatives | |

| 2001 | |

| Bhutan Patel | |

| CEO | |

| 50 Employees | |

| IN | |

| GJ | |

| Ahmedabad |

Communication

| No. 7, Khodiyar Estate, Near Sakariba Estate, Behind Indo German Tool Room, Phase-4, GIDC, Vatva, Ahmedabad – 382 445, Gujarat, India. | |

| +(91)-9426064890 | |

About Business

Business Summary

ETO Sterilizer Manufacturer-Ethylene Oxide Sterilizer, Hospital ETO Sterilizer, Ethylene Oxide Gas Sterilizer from Ahmedabad, India - ETO Sterilizer

Business Description

Krishna Engineering - Premier ETO Sterilizer Producer; Delivering Expertise in ETO Sterilization Globally – Ahmedabad, India.

Welcome to Krishna Engineering, your trusted partner in the world of sterilization technology. Since our inception in the year 2000, we have been at the forefront of manufacturing and exporting a diverse range of ETO (Ethylene Oxide) sterilizers, vessels, ribbon blenders, tray dryers, vacuum dryers, ETO sterilization equipment, and steam sterilizers!!

We provide an extensive selection of ETO sterilizers, which includes the following: bio medical steam sterilizer, continuous steam sterilizers, cylindrical steam sterilizer, food sterilizers, fumigation chambers, herbal steam sterilizers, high pressure steam sterilizer, horizontal steam sterilizer, hospital steam sterilizers, industrial retort, instrument steam sterilizer, medical auto claim, Pharma steam sterilizers, and ribbon blender.Because of their versatility, our extremely effective ETO sterilizers can be found in a variety of industries, including pharmaceuticals, hospitals, medical, chemical, food and beverage, packaging, and other areas. To provide quality assurance, performance, and dependability for ETO sterilizers, as well as customer satisfaction, continuous learning, and new solution options to clients located all over the world.Our mission is to provide innovation, development, and adoption of state-of-the-art technology to our precious customers in order to improve the productivity and cost effectiveness of ETO sterilizers.We are able to give the highest possible output quality thanks to the team of highly qualified engineers and committed specialists that we have at our disposal. Our ability to successfully collaborate as a group is one of our greatest strengths. At every stage of production, from the initial procurement of raw materials to the final shipment of finished goods, each and every one of our products is subjected to stringent quality control checks across a wide range of parameters.

In the year 2000, we launched our "ETO sterilizers" project. Since our company's founding in this millennium year, we have established long-term relationships with our global customer base and earned a reputation as one of the top most manufacturers and exporters of ETO sterilizer, vessels, ribbon blender, tray dryer, vacuum dryer, ETO sterilization, and steam sterilization equipment.In the space of roughly a decade and a half, we have been able to acquire manufacturing facilities of an international standard that are equipped with cutting-edge technology.

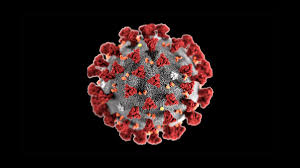

Krishna Engineering: The Picture is Business Represenational

We would like to take this opportunity to introduce ourselves as your reliable partner in the field of sterilization technology here at Krishna Engineering. Since our company's founding in the year 2000, we have been at the forefront of the ETO (Ethylene Oxide) sterilizers, vessels, ribbon blenders, tray dryers, vacuum dryers, ETO sterilization equipment, and steam sterilizers manufacturing and exporting industries. Our product lineup includes a wide variety of ETO sterilization equipment. Our path has been characterized by an uncompromising commitment to quality, innovation, and the happiness of our customers; as a result, we are recognized as one of the most respectable names in this sector.

Both of Our Goals and Our Vision:

At Krishna Engineering, we are directed by a distinct vision and mission, which serves as the impetus for all of our activities.

Our valued customers come from a wide range of industries, and we want to be able to provide them with solutions that are cutting-edge, dependable, and economical. Our vision is to become the global leader in sterilization technology.

Mission Statement: Our mission is to continually offer high-quality ETO sterilizers, steam sterilizers, and associated equipment while embracing cutting-edge technology, promoting continuous learning, and assuring client satisfaction.

A Product Range Comprised of Multiple Varieties:

Our product line includes a wide variety of processing and sterilization equipment, making it suitable for use in a variety of different business sectors. We are aware that sterilization is an essential component of a variety of industries; hence, we provide a broad selection of goods in order to cater to the specific requirements of each sector. Among the products that we offer are:

The Bio Medical Steam Sterilizer guarantees the greatest possible level of sterility for all types of medical supplies and equipment.

Continuous Steam Sterilizers are ideally suited for use in medical and pharmaceutical settings since they are designed to ensure that sterilization procedures proceed without interruption.

Cylindrical Steam Sterilizers are sterilizers with precision engineering that are designed to disinfect cylindrical things in an effective and consistent manner.

Food Sterilizers: Meeting the severe criteria of the food and beverage sector for the safe and hygienic processing of foods and beverages.

Fumigation Chambers are specialized chambers that can be customized for efficient use in the fumigation process.

Herbal Steam Sterilizers are steam sterilizers that have been built specifically for the herbal and botanical industries. This ensures that any valuable characteristics are kept intact during the sterilization process.

The High-Pressure Steam Sterilizer is specifically designed to meet the requirements of a wide range of applications requiring high-pressure sterilization.

The Horizontal Steam Sterilizer provides laboratories and medical facilities with space-efficient sterilizing options.

Hospital Steam Sterilizers are able to precisely meet the sterilization needs of healthcare establishments.

Industrial Retorts are multi-purpose retort systems that are used for the sterilization and preservation of packaged goods.

The Instrument Steam Sterilizer is responsible for ensuring the sterility of sensitive instruments that are utilized in the sectors of research and medicine.

The Medical Autoclave is the most advanced autoclave technology now available for the sterilization of medical equipment.

Pharma Steam Sterilizers are solutions for compliant sterilization that are adapted specifically for pharmaceutical manufacturing.

A Ribbon Blender is an effective piece of mixing and blending equipment that may be utilized in a range of different sectors.

Over the course of its existence, Krishna Engineering has established long-lasting connections with clients located all over the world. As a result, the company has garnered a reputation for being an industry leader in the production and export of sterilizing equipment. Because of our commitment to quality and our adherence to international standards, we have become a reliable business partner in a variety of industries, including the pharmaceutical industry, hospitals, the medical industry, the chemical industry, the food and beverage industry, and packaging, amongst many others.

Facilities for Manufacturing of World-Class Standing:

During the course of our journey, which has spanned more than a decade, we have made major investments in production facilities that are state-of-the-art and equipped with extremely current technology. These facilities are a demonstration of our dedication to technological advancement and operational effectiveness. Our manufacturing procedures were developed to guarantee that every product that we ship out of our facility is of the highest possible quality and can be relied upon.

At Krishna Engineering, we are well aware that our team is the single most important and valuable asset that we possess. The key to our success has been the hard work and dedication of our team, which consists of highly skilled engineers and other experts. We believe that effective collaboration among team members is the primary factor that will allow us to meet and exceed the standards set by our customers.

Our Dedication to the Maintenance of High Quality:

The pursuit of quality underlies each and every one of our endeavors. Every stage of the manufacturing process that we go through is subjected to stringent monitoring and testing, beginning with the procurement of raw materials and continuing until the shipment of finished goods. Our sterilizers and other pieces of equipment are put through rigorous quality control procedures so that we can guarantee that they are up to par with or even better than industry standards. Our global clientele have placed a greater level of faith in us as a company as a direct result of our dedication to quality control.

Adoption of New Technologies and Innovation:

In a technical landscape that is constantly shifting, staying one step ahead of the curve is absolutely necessary. In the realm of ETO sterilizers, we at Krishna Engineering are always looking for ways to improve our efficiency and lower our costs, therefore we encourage new ideas and strive to use the most cutting-edge technology available. Our research and development staff puts in long hours to ensure that our customers have access to the most innovative solutions available. This helps to ensure that our customers are always at the forefront of the latest sterilizing technology.

Approach that Is Focused on the Customer:

The satisfaction of our consumers is the primary focus of all that we do. When it comes to providing personalized solutions, we feel that having a solid understanding of the specific needs and difficulties faced by our customers is absolutely necessary. Our strategy places a strong emphasis on the client, and it centers on maintaining open lines of contact with them, being responsive to their needs, and ensuring that the products we provide both meet and exceed their expectations. We are quite proud of our capacity to form long-lasting partnerships with our clients that are founded on trust and the promotion of each other's success.

Responsibility Towards the Environment:

As responsible corporate citizens, we are aware of the impact that our operations have on the environment. Our equipment for sterilization is designed to be as effective as possible while also being environmentally friendly. We make it a priority to reduce the amount of garbage that we produce and the amount of energy that we use while conducting our business. We are dedicated to making a contribution toward a future that is greener and more sustainable.

The trip that took us from Ahmedabad, India, to the center of the world stage has been an extraordinary one. We have been quite successful in penetrating new international markets, and as a result, we now have a global footprint that extends across multiple continents. We are happy to be able to service consumers from all over the world, as our dedication to quality, innovation, and the complete happiness of our customers knows no bounds.

This is Our Guarantee to You:

At Krishna Engineering, we provide our clients with a solemn guarantee, which is as follows:

Assurance of Quality: Each and every one of our goods is put through a series of stringent quality tests to guarantee that they are up to par in terms of both performance and dependability.

Innovation: We are dedicated to maintaining our position at the forefront of sterilization technology and developing creative solutions that meet the ever-evolving demands of the industry.

Customer Satisfaction: The achievement of your contentment is our top priority. We are committed to gaining an understanding of the specific needs you have articulated and to delivering solutions that go beyond those needs.

Our track record of reliability and on-time delivery speaks for itself, and it's a record that we're proud of. You can rely on us to provide exactly what we've promised, every single time.

Environmental Responsibility: We are dedicated to the principles of sustainability and environmental responsibility, and we work hard to reduce the amount of harm that we cause to the earth.

The final word:

We at Krishna Engineering are not simply a business; rather, we are a group of enthusiastic people who are committed to pushing the state of the art in sterilization technology. Because of our unyielding dedication to quality, innovation, and the complete fulfillment of our clients' needs, we have risen to the position of market leader in this sector. The key components of our success are our widespread presence across the globe, our state-of-the-art production facilities, and our highly skilled and experienced workforce.

As we look to the future, one of our primary goals is to continue pushing the limits of what is currently considered possible in terms of sterilizing technology. We would be honored if you would accompany us on this adventure, during which we will strive to achieve new levels of brilliance and have a beneficial influence on businesses and markets all around the world.

We are grateful that you have chosen Krishna Engineering to be your reliable partner in the sterilization technology industry. We are excited to be of service to you and to go above and beyond your expectations.

For more information, please call us on phone +919426064890 or visit our website here: Krishna Engineering

Products / Services

Products

- Bio medical steam sterilizer

- Continuous steam sterilizers

- Cylindrical steam sterilizer

- Food sterilizers

- Fumigation chambers

- Herbal steam sterilizers

Platform Enhanced Sections and Articles

Article by Siachen Editors to aid the customer in decision making

A Comprehensive Guide for Evaluating a Vendor for Sterilization Equipment:

Written for the client guidance by Siachen editors to help the potential customers of this business in evaluating and zeroing down on the best provider to place the order.

Introduction:

In today's rapidly evolving world, selecting the right vendor for products and services is a critical decision for customers across various industries. When it comes to choosing a vendor for sterilization equipment, particularly in fields such as healthcare, food processing, or pharmaceuticals, making the right choice can have a profound impact on product quality, safety, and overall business success. To assist customers in their evaluation process, we have compiled a comprehensive guide outlining the key factors to consider when evaluating potential vendors for various types of sterilization equipment. In this article, we will focus on six distinct categories of sterilization equipment: Biomedical Steam Sterilizers, Continuous Steam Sterilizers, Cylindrical Steam Sterilizers, Food Sterilizers, Fumigation Chambers, and Herbal Steam Sterilizers.

1. Biomedical Steam Sterilizers

1.1 Technical Specifications

Chamber Capacity: Ensure the sterilizer's chamber size meets your specific needs.

Temperature and Pressure Controls: Verify if the equipment provides precise control over temperature and pressure parameters.

Cycle Time: Evaluate the cycle time required for sterilization processes.

Validation and Compliance: Check for compliance with relevant industry standards (e.g., FDA, ISO).

1.2 Service and Maintenance

Warranty and Support: Understand the vendor's warranty terms and post-sales support options.

Calibration and Validation: Inquire about calibration and validation services provided by the vendor.

Availability of Spare Parts: Assess the availability and cost of spare parts.

1.3 Cost Considerations

Initial Investment: Compare the upfront costs of different vendors.

Operating Costs: Evaluate energy consumption, water usage, and maintenance expenses.

Total Cost of Ownership (TCO): Consider TCO over the product's lifespan.

2. Continuous Steam Sterilizers

2.1 Throughput and Efficiency

Throughput Capacity: Assess the sterilizer's ability to handle your production volume.

Energy Efficiency: Inquire about the equipment's energy-saving features.

Automation and Integration: Determine if the equipment can be seamlessly integrated into your production line.

2.2 Reliability and Durability

Material Quality: Evaluate the materials used in construction for durability.

Service History: Research the vendor's track record for reliability and minimal downtime.

Maintenance Requirements: Understand the maintenance schedule and costs.

2.3 Compliance and Validation

Regulatory Compliance: Ensure the sterilizer meets regulatory requirements for your industry.

Validation Protocols: Verify if the vendor provides documentation and support for validation processes.

Data Logging and Traceability: Check if the equipment offers data logging capabilities for quality control.

3. Cylindrical Steam Sterilizers

3.1 Customization and Flexibility

Configuration Options: Evaluate the availability of customizable features to meet specific needs.

Size Variability: Determine if the sterilizer can accommodate various load sizes.

Cycle Programming: Assess the flexibility in programming different sterilization cycles.

3.2 Safety and User-Friendliness

Safety Features: Inspect the equipment for safety features like pressure relief valves and emergency shut-off.

User Interface: Evaluate the ease of use and user-friendly interface.

Training and Documentation: Check if the vendor provides training and comprehensive documentation.

3.3 Environmental Considerations

Environmental Impact: Assess the sterilizer's environmental footprint, including emissions and waste.

Compliance with Eco Standards: Verify if the equipment adheres to eco-friendly standards and regulations.

4. Food Sterilizers

4.1 Food Safety and Quality

Temperature Control: Ensure the equipment can maintain precise temperature levels.

Preservation of Nutritional Value: Evaluate the sterilization method's impact on food quality.

Packaging Compatibility: Check if the sterilizer is compatible with your food packaging materials.

4.2 Regulatory Compliance

Food Safety Regulations: Confirm that the sterilizer complies with food safety regulations.

HACCP Compatibility: Determine if the equipment aligns with Hazard Analysis and Critical Control Points (HACCP) principles.

Auditing and Certification: Verify the vendor's certifications and auditing history.

4.3 Cost Efficiency

Energy Efficiency: Assess the equipment's energy consumption and operational costs.

Production Efficiency: Consider the impact on production speed and overall efficiency.

Maintenance Costs: Compare the long-term maintenance costs of different sterilization methods.

5. Fumigation Chambers

5.1 Fumigation Methodology

Fumigant Type: Evaluate the suitability of the fumigant used for your specific needs.

Application Precision: Assess the control and precision of fumigation processes.

Residue Management: Inquire about residue management and disposal procedures.

5.2 Safety and Health Considerations

Worker Safety: Ensure the fumigation chamber provides adequate protection for workers.

Environmental Impact: Assess the environmental impact of fumigation methods.

Regulatory Compliance: Verify compliance with pesticide and fumigation regulations.

5.3 Monitoring and Data Logging

Real-time Monitoring: Check if the equipment offers real-time monitoring of fumigation processes.

Data Logging and Reporting: Evaluate the data logging and reporting capabilities for compliance records.

6. Herbal Steam Sterilizers:

6.1 Herb Preservation

Temperature Control: Ensure precise temperature control to preserve the potency of herbs.

Humidity Control: Assess the ability to maintain optimal humidity levels for herbal sterilization.

Customization for Herb Types: Determine if the sterilizer can accommodate various types of herbs.

6.2 Traditional Knowledge Integration

Traditional Methods: Inquire if the equipment allows for the incorporation of traditional sterilization methods.

Herbal Medicine Expertise: Collaborate with vendors who understand herbal medicine practices.

6.3 Sustainability and Ethical Sourcing

Sustainable Practices: Verify if the vendor follows sustainable and ethical sourcing practices.

Certifications: Look for certifications related to herbal product quality and sustainability.

Conclusion:

In conclusion, the selection of a vendor for sterilization equipment requires meticulous evaluation across multiple dimensions, including technical specifications, service and maintenance, cost considerations, compliance, and environmental factors. By carefully considering these factors within the context of your specific industry and application, you can make an informed decision that not only meets your immediate needs but also contributes to the long-term success and sustainability of your business. Remember that each category of sterilization equipment comes with its unique set of considerations, so adapt your evaluation criteria accordingly to ensure the best fit for your requirements.

Last five profiles from the category:

-

Camlock Fittings – Leading supplier of high-quality camlock fittings, stainless steel ball valves, and brew hardware for various industries – Queensland, Australia.

siachen.com/camlockfittings

Unit 1 10 Boron Street Sumner Park, QLD 4074 Australia land_line : 1300 988 963 -

WeCustomBoxes – Custom Packaging Solutions to Enhance Your Brand with High-Quality, Affordable, and Eco-Friendly Options – Katy, Texas, USA.

siachen.com/wecustomboxes

1997 Katy Mills Blvd, Katy TX 77494, United States. land_line : 12817864001 -

Doocan – India’s best furniture manufacturer leveraging a tech-powered platform for global B2B marketplace solutions – Wilmington, Delaware, United States.

siachen.com/doocan

300 Delaware Ave. Suite 210 #265, Wilmington , DE - 19801, United States. land_line : +919634375566 -

Sydney Steel Fabricators – Premier provider of comprehensive metal services including steel fabrication, welding, and metal supply since 2010 – New South Wales, Australia.

siachen.com/sydneysteelfabricators

Shop 7/363 Sussex St, Sydney NSW 2000, Australia. -

Adco DispleTech – Leading providers of high-quality retail display fixtures and store supplies with over 60 years of innovation – Montreal, Quebec, Canada.

siachen.com/displetechcorp

1310 Rue Chabanel O, Montreal, QC, Canada. land_line : +5143812396